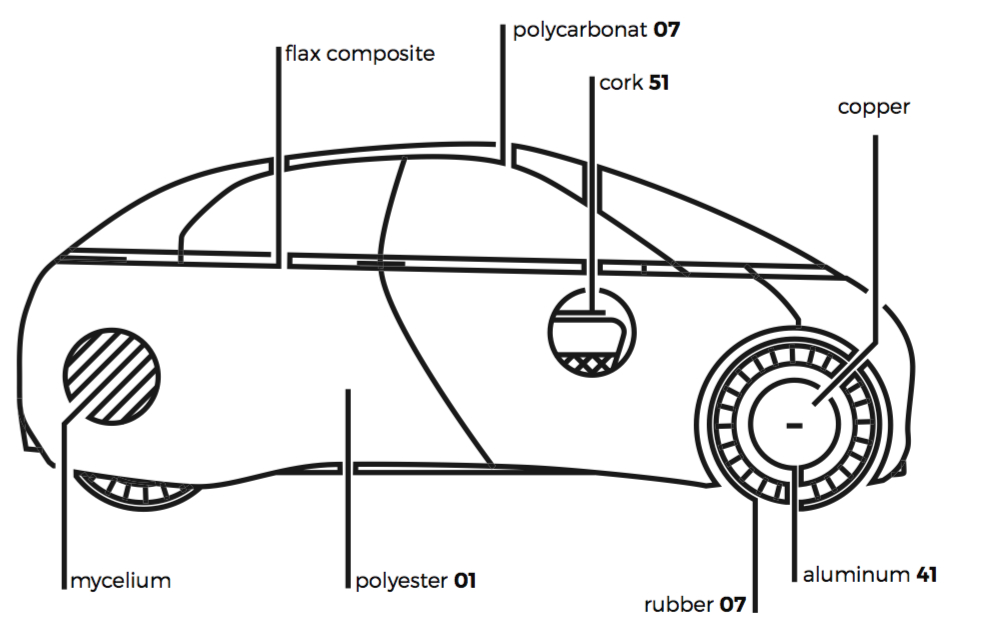

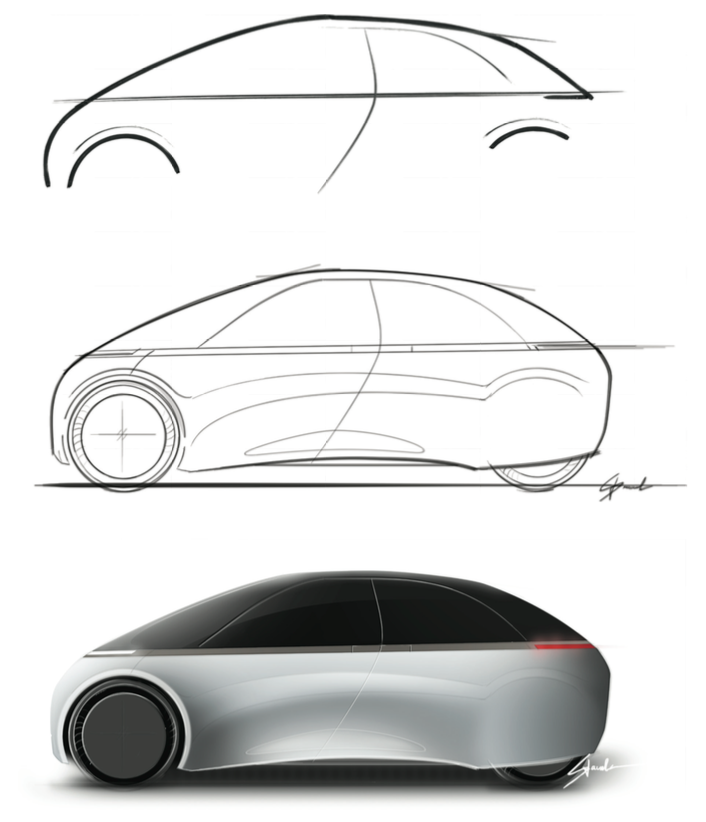

The bodywork of the car is made out of grown mushroom material. The mycelium is enclosed by flax composite parts.

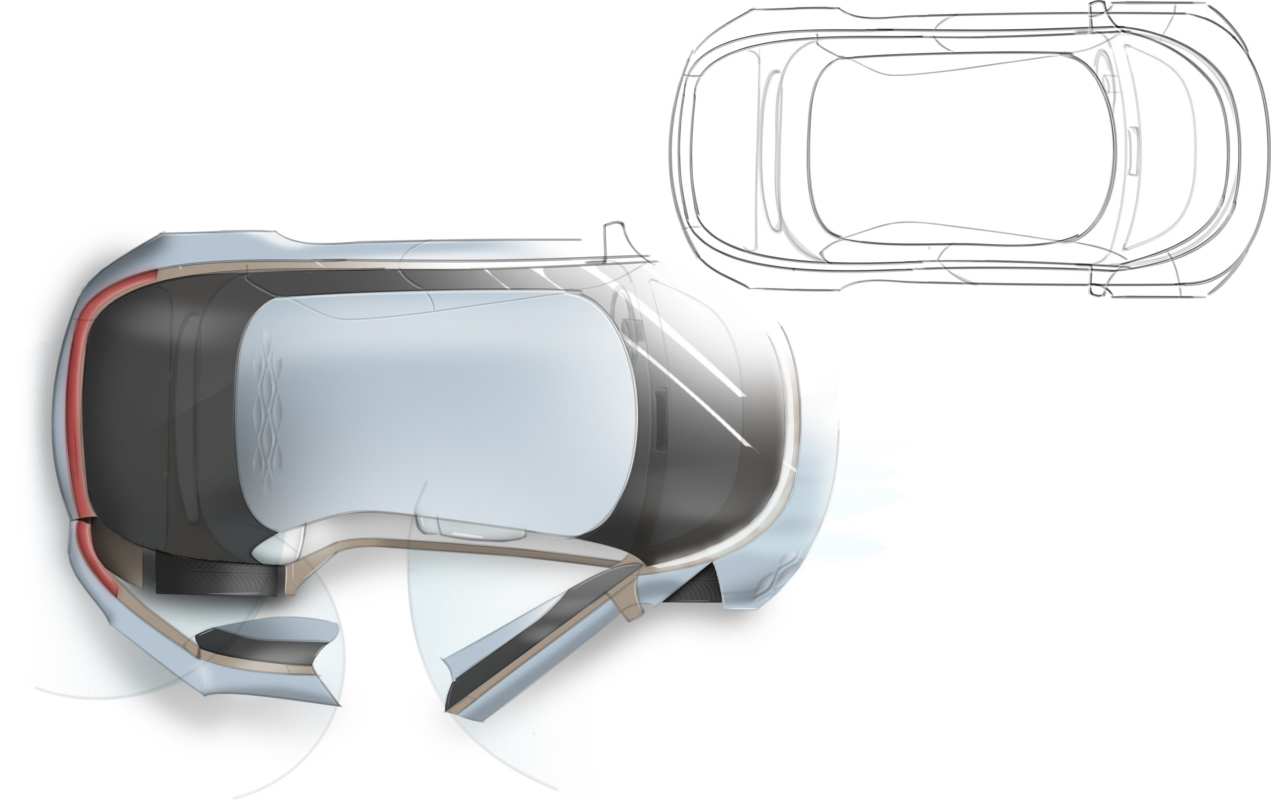

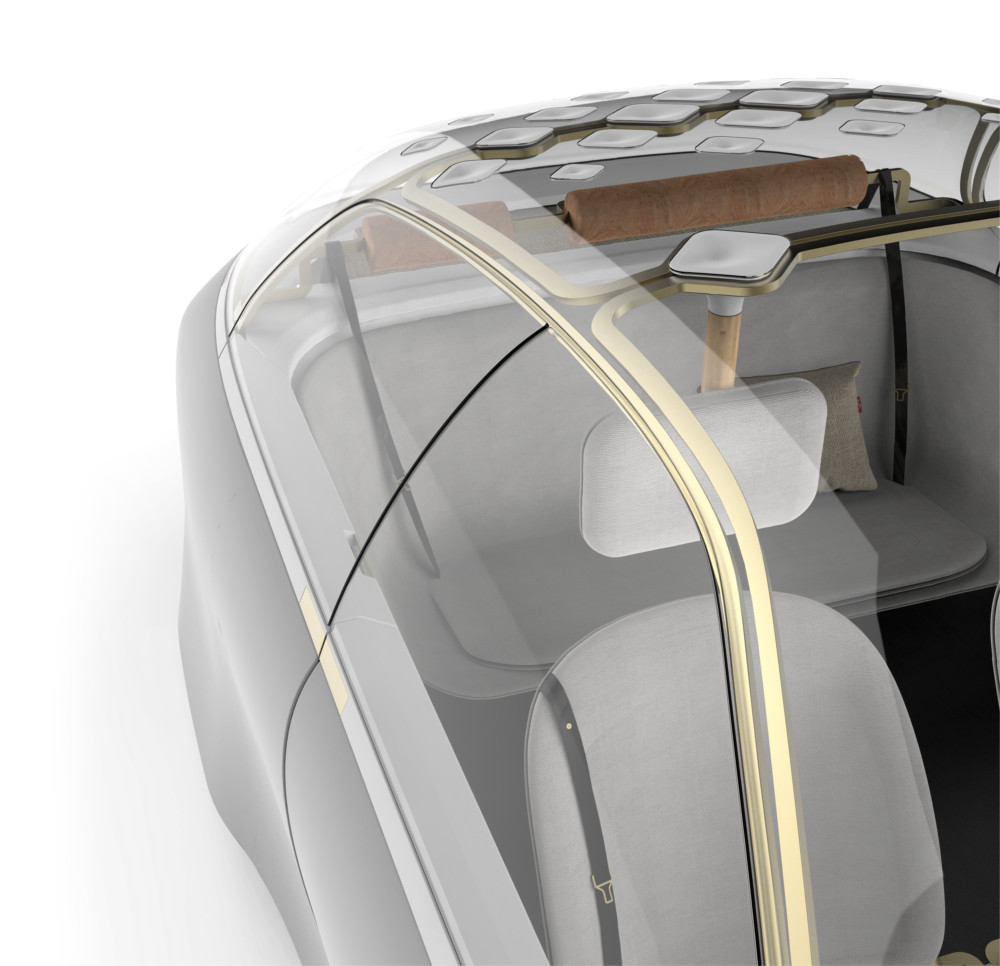

Golf ball like dimples are mixing faster and slower air layers and bending the air stream towards the surface. The separation area gets smaller and the drag coefficient decreases from 0.22 to 0.19. They are also the connection between the frame and the glazing.

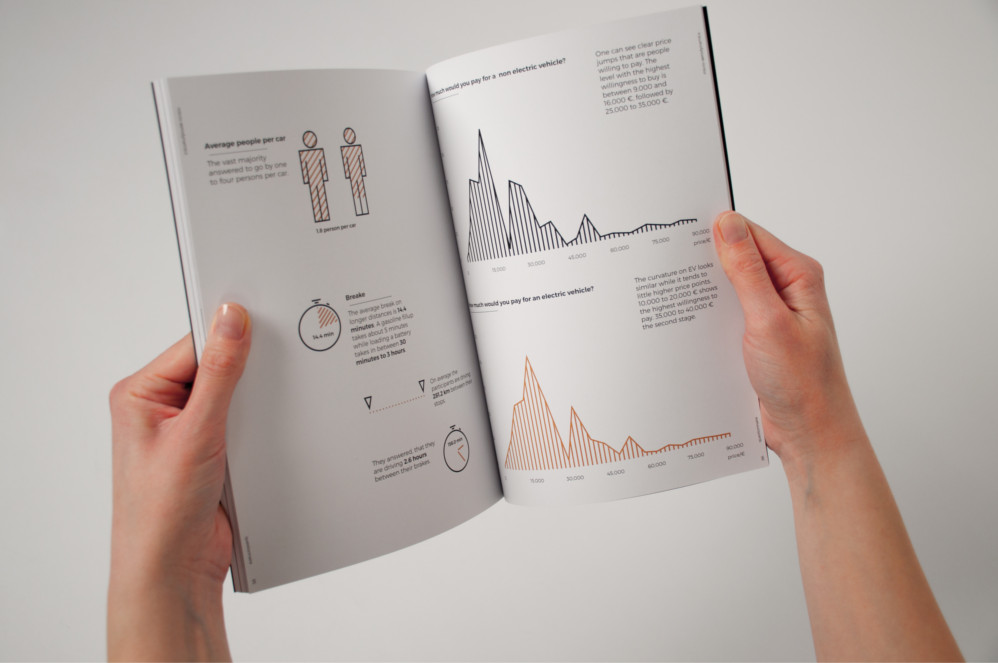

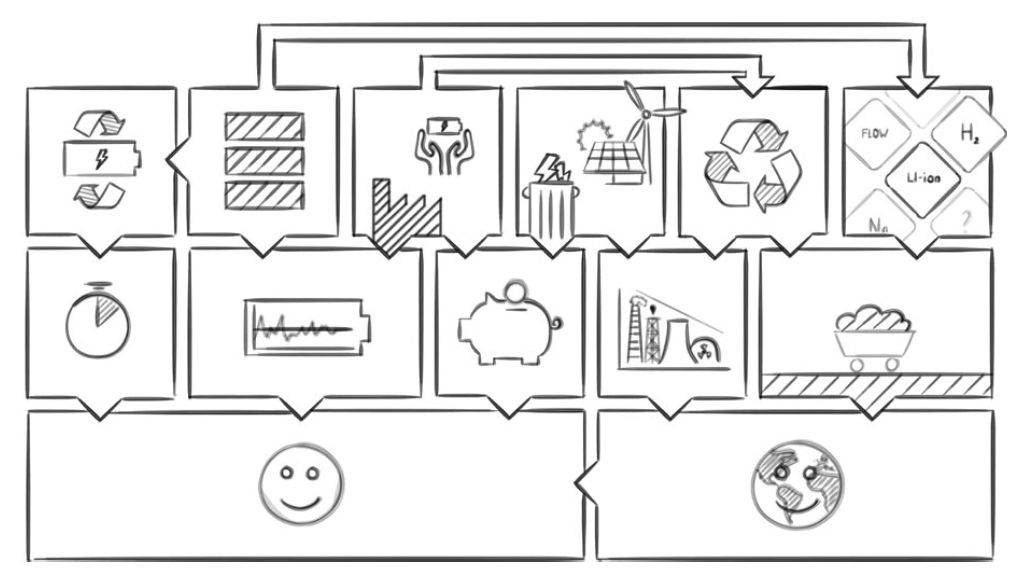

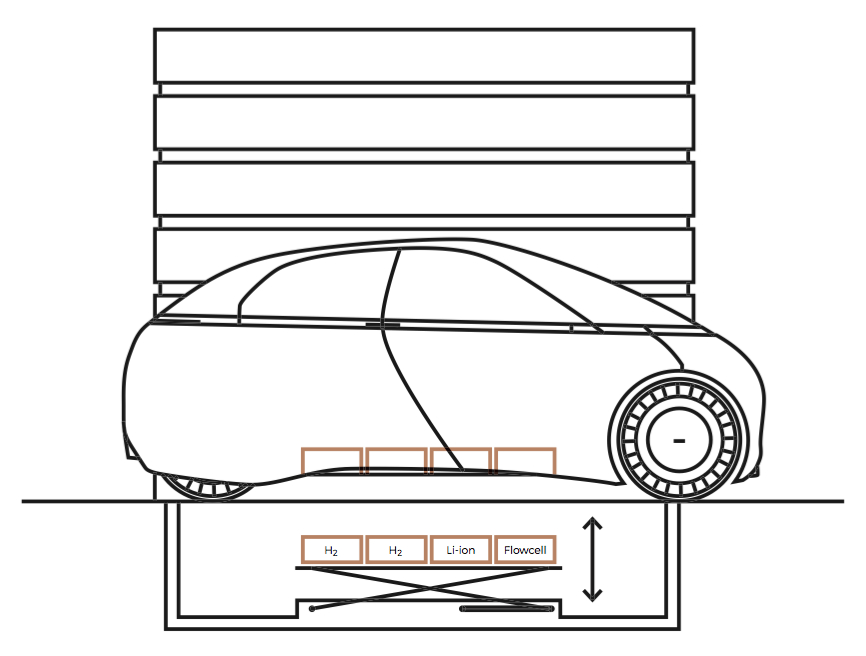

The battery swap system is standardized to be open for every type of vehicle. It buffers renewable energy that otherwise stays unused and builds an intelligent energy grid, that allows an extension in sustainable energy. It makes a competition in battery technology possible. By shifting the responsibility to the operator, the user gets a better battery technology on a better price tag.

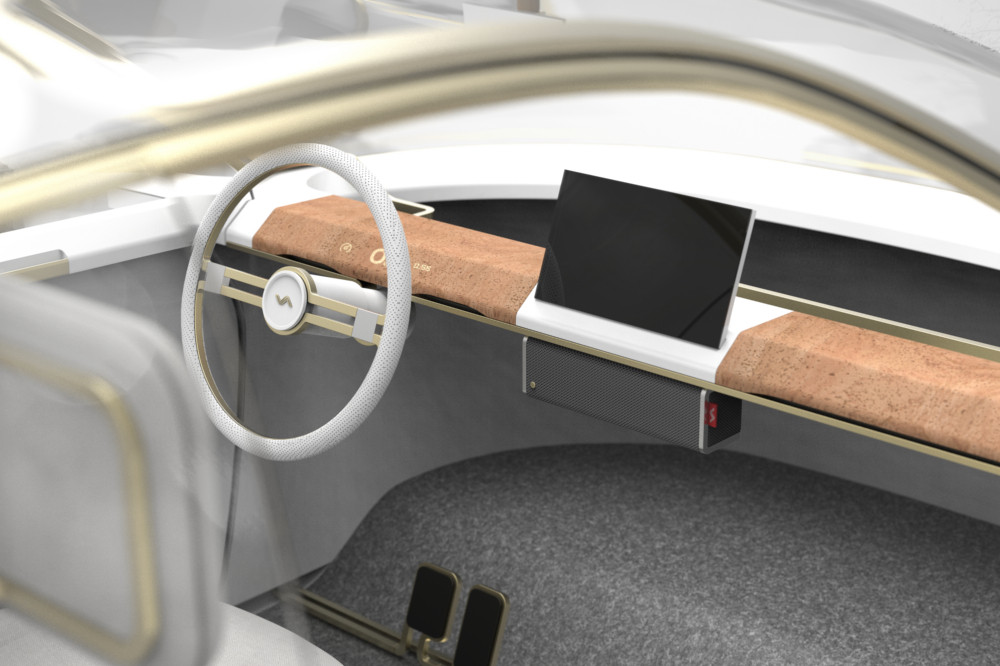

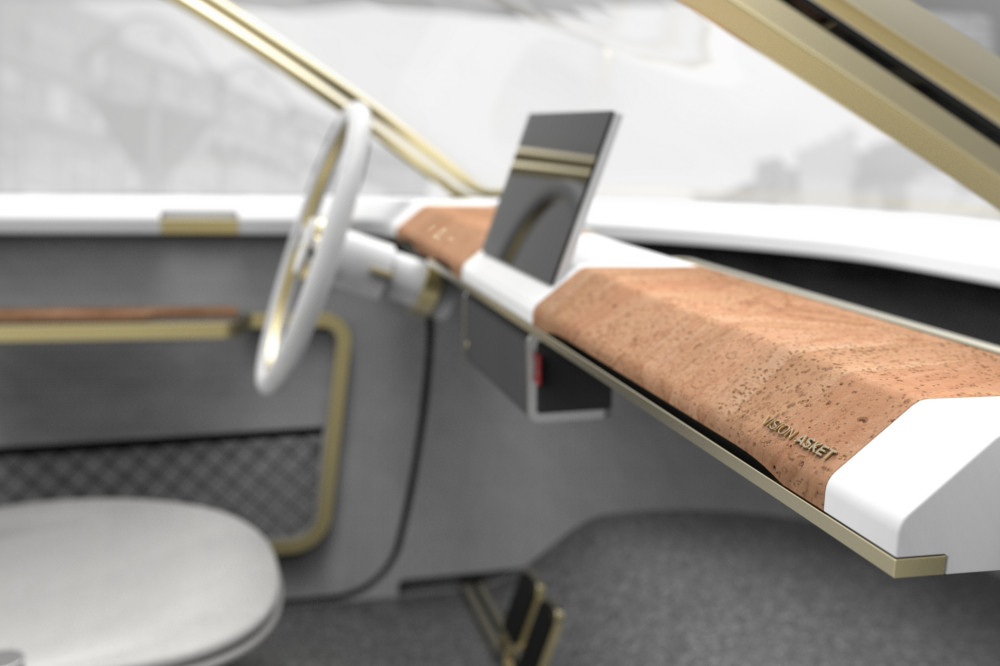

The display of the car can be undocked and used as a tablet computer. The sound system is a Bluetooth speaker that can also be taken out of the car. This leads to less electronic waste and gives the user a seamless entertainment experience.

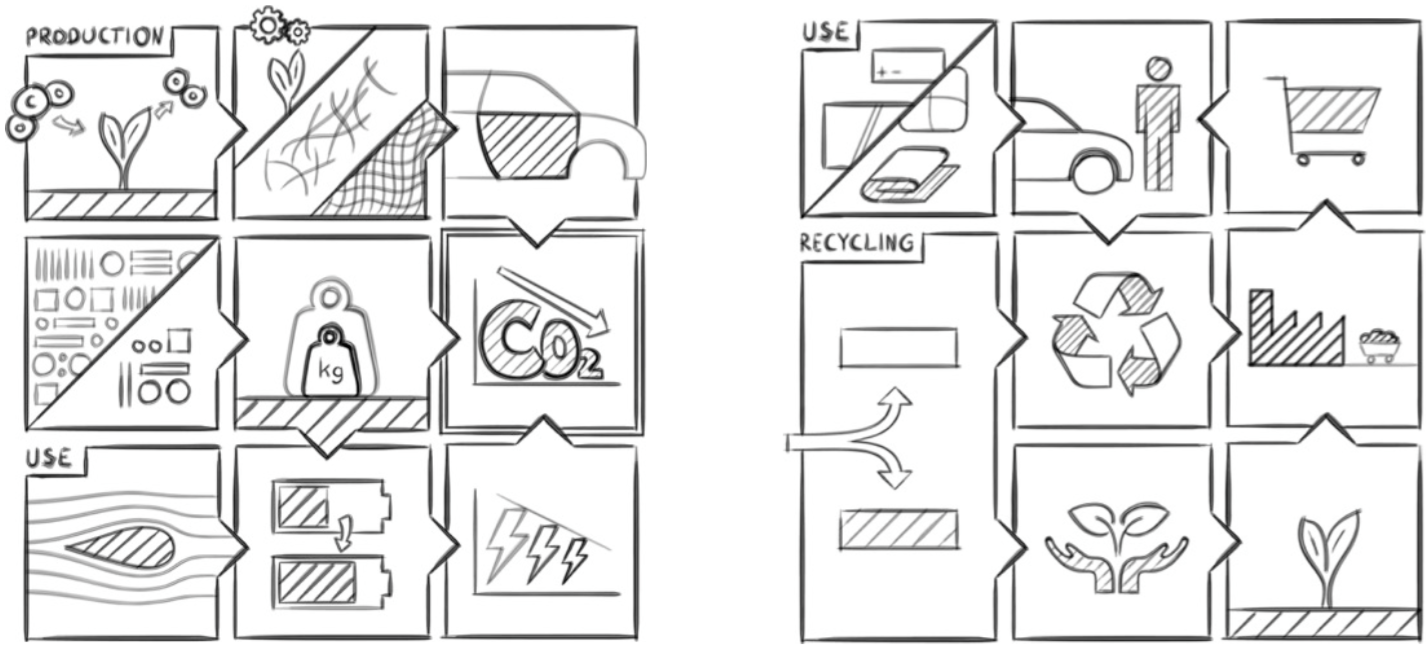

Standardized reusable RFID tags on every part make a machine controlled recycling possible. They get removed during the process and reused in new products. Then the single parts can be recycled or bio degraded.